Engineering

Dosing systems

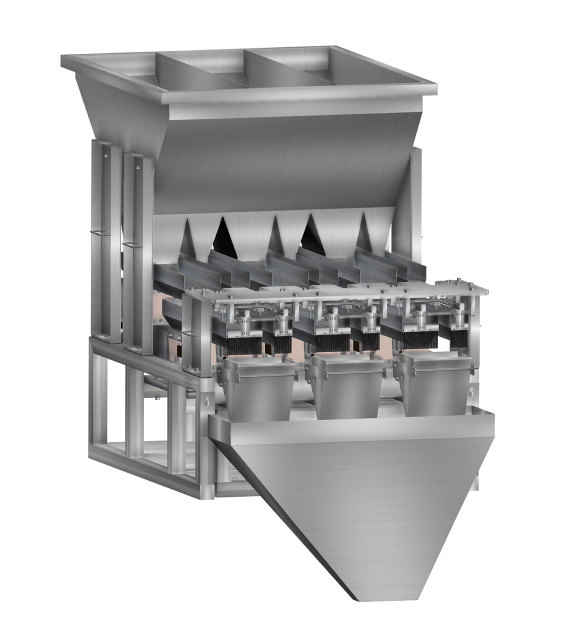

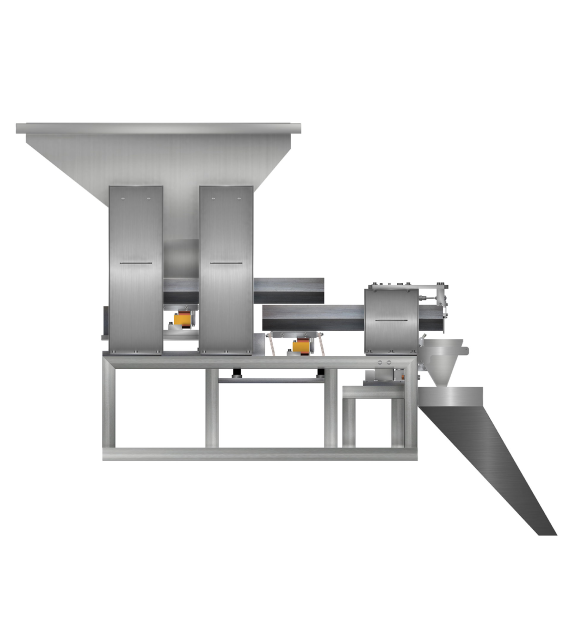

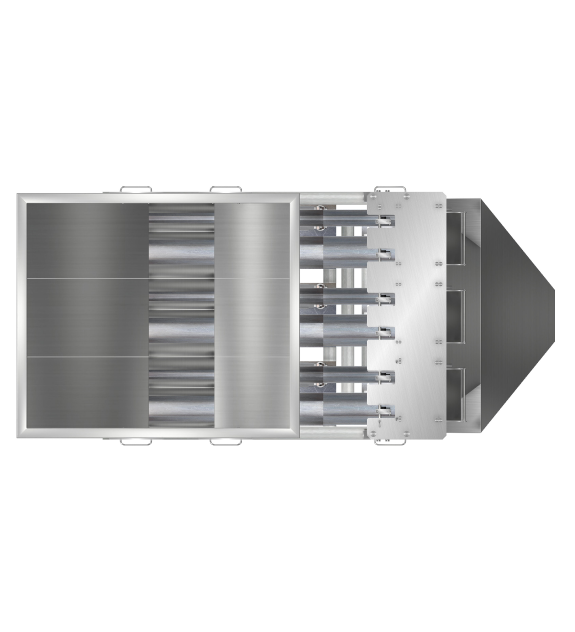

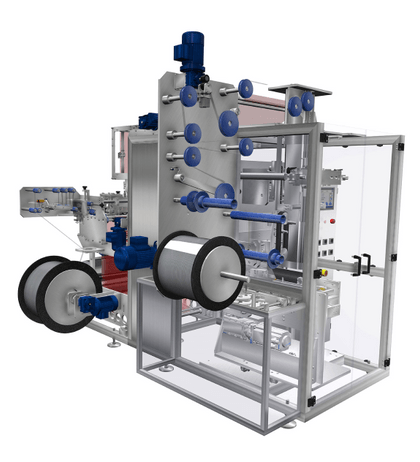

Linear bucket scale – vibro feeding

Characteristics

| Scaling | In grams |

| Capacity [weigh-ins/min] | Depends on the number of scales ( 1 scale – 10 weigh-ins / minute) |

| Bucket size [L] | 2; 3; 5 |

| Weigh-in range [g] | 20-1000;1000-5000;10000-25000 |

| Weigh-in accuracy | ±2g;±10g;±20g |

| Products it is applicable to | seeds, dried fruits, cornflakes, frozen fruits, etc. |

| Device parameterization | On the package-forming machine’s touch panel. |

Machine building for packaging industries

The device transports the product using vibrating paths from the receiving hopper into the buckets in which measuring takes place. When measuring cells reach the limit, feeding is stopped and the package-forming machine is informed that the dosing system is ready. Each bucket is fed by four vibrating paths. When the bucket measuring cells detect that a given measure will soon be achieved, only the narrow vibrating paths continue with feeding. The device has proven reliable for weighing dry, sticky non-uniformed size materials. Two levels of vibrating paths ensure even feeding of the mass, even if there is a clog inside the hopper.

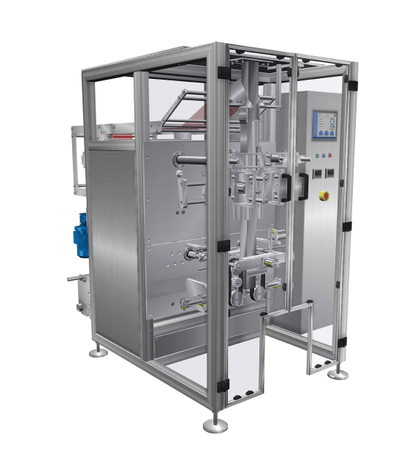

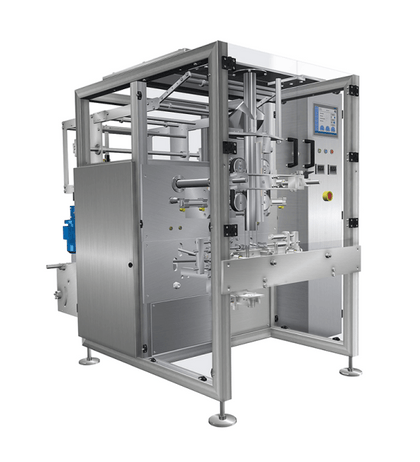

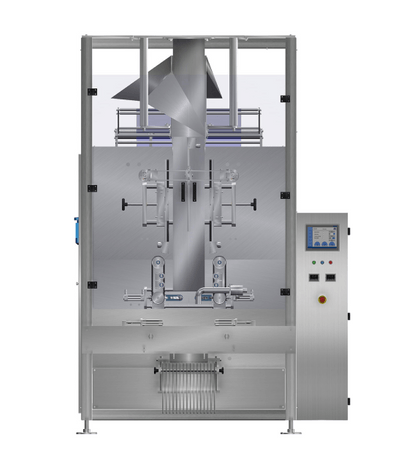

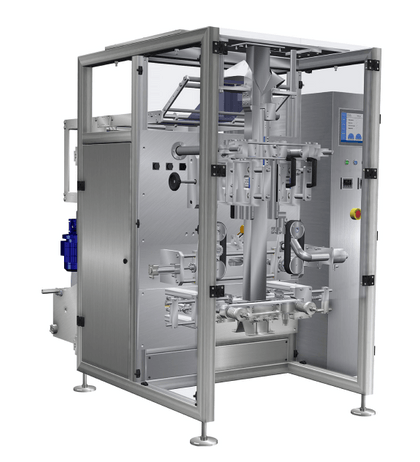

The device is compatible with vertical bag forming machines:

Process lines compatible with device: