SYSTEM SOLUTIONS

Machine building for packaging industries

Working with tech teams of our partners we have successfully executed complete arrangement and equipping of various production facilities. So today we can boast of the experience gained in the automatization of the production and packaging:

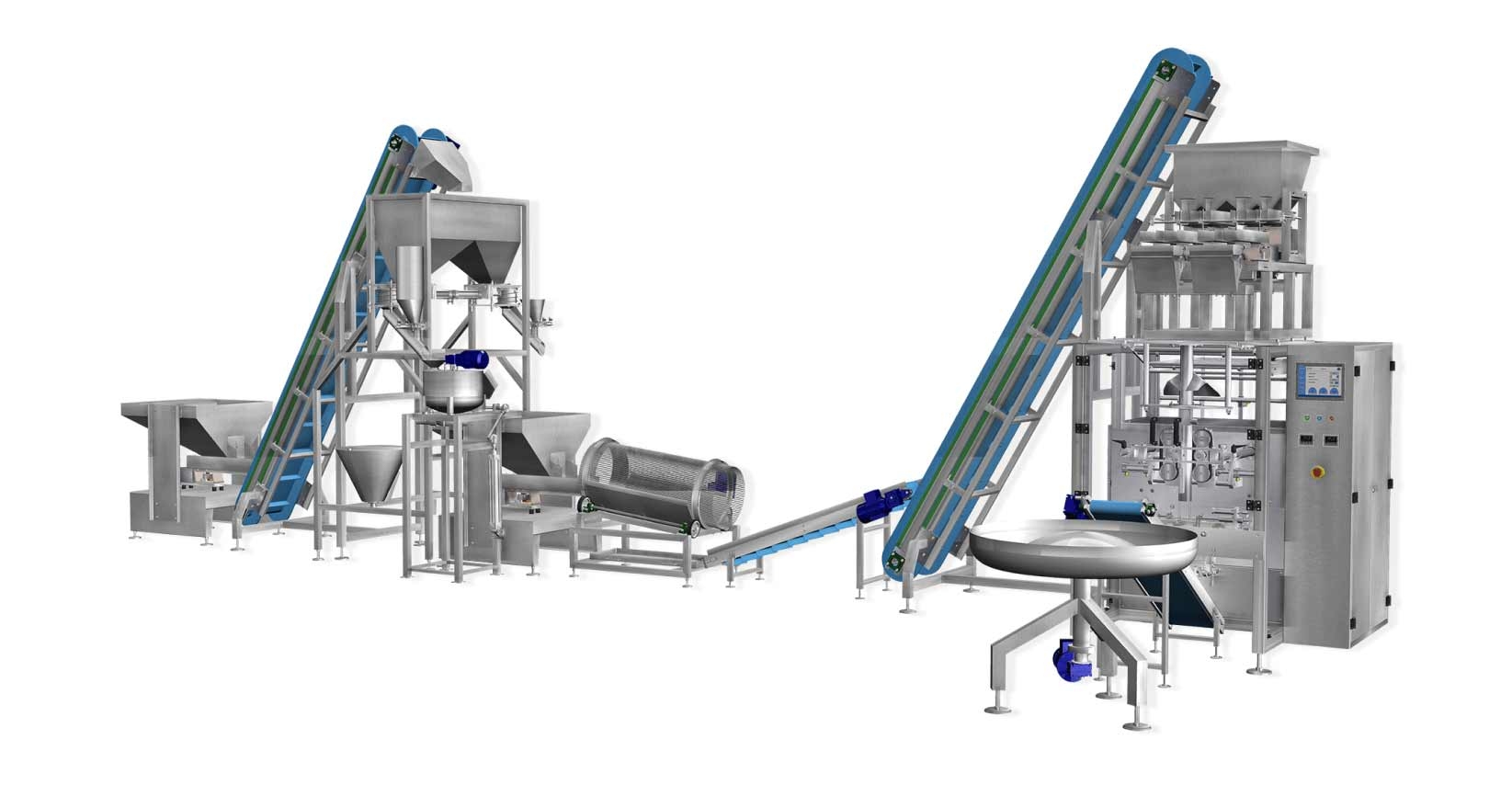

System solution for packaging sticky grain matter MH

System solution for packaging sticky powder matter into bags VP

Solution system for packaging dry powder matter into bags HP

System solution for packaging finely grained matter into bags ZD

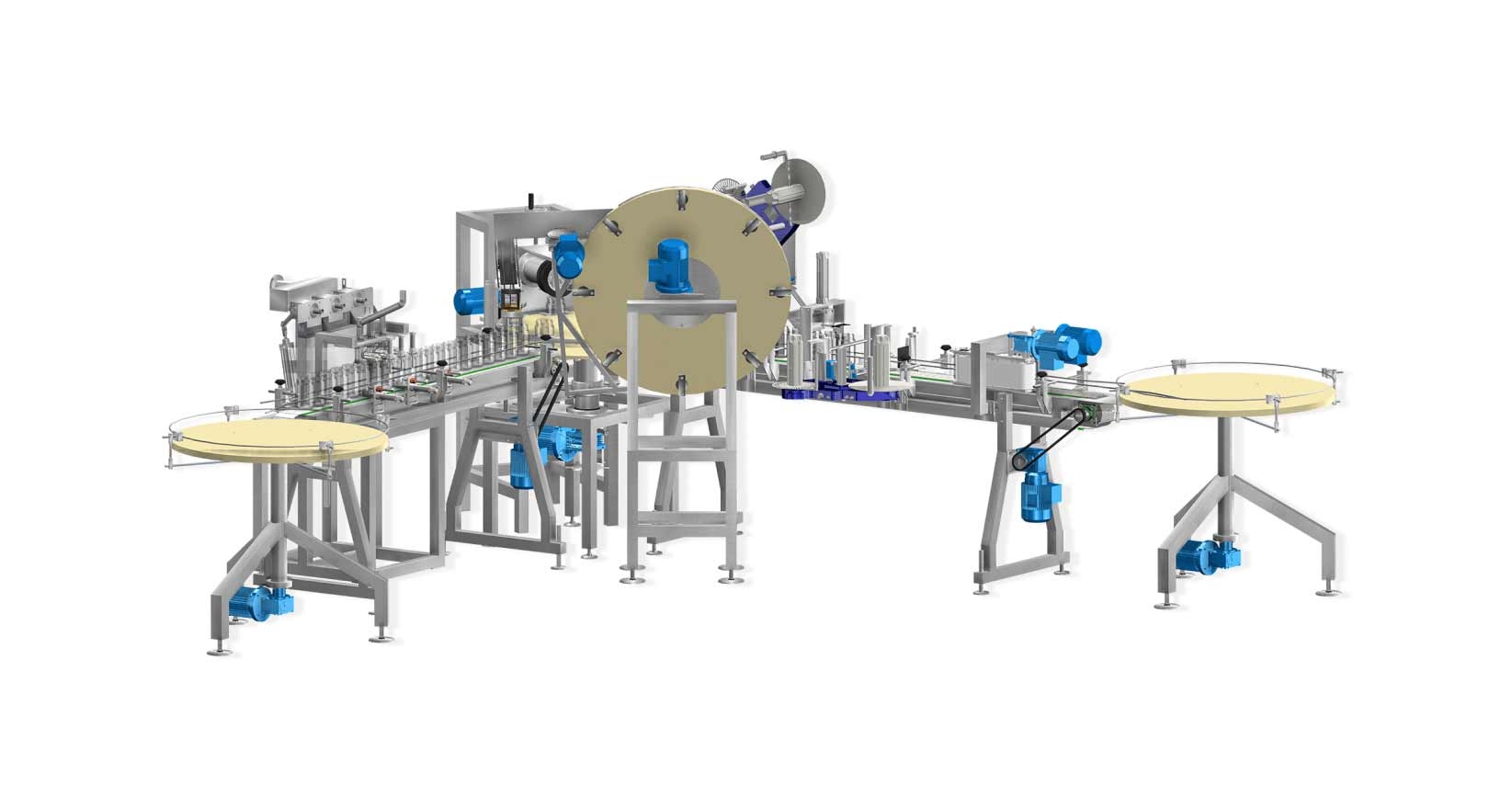

Jar feeding system

System solution for packaging sticky grain matter into bags GV

System solution for packaging grain matter into bags GT

System solution for packaging grain matter into bags MH

System solution for packaging sugar into cubes

System solution for packaging and popping popcorn

In order to equip a single production facility for packaging and to train personnel to operate the equipment efficiently, it is necessary to carry out:

Business performance depends on many factors. Modern technological breakthroughs have changed today’s approach to problems and have in many ways accelerated production methods. Guided by experience we can claim that the main factor that affects successful business performance is it’s team.

BENEFITS OF OUR INTEGRATED SYSTEMS ARE: